Diesel Care AS

Solution

70 years of experiense, specialist in diesel fuel. Make your tank clean, suction line clean. Recover your diesel fuel back to retail diesel EN590.

Low ppm - less particles.

ABOUT

Recover Diesel

Recover your waste diesel to retail EN590.

TQM methods brings your diesel, water absorbent treatment down to 50ppm. Particals down to a minimum. Laboratories tested to "on spec". Water and dirty diesel back to retail diesel.

TQM methods brings your diesel, water absorbent treatment down to 50ppm. Particals down to a minimum. Laboratories tested to "on spec". Water and dirty diesel back to retail diesel.

Tank Control - Cleaning - Recover

Makes your tank clean.

Take care of waste for recovery back to retail.

Sample control, camera control.

No water by cleaning.

Do it Diesel Care way.

All sizes, to depot tank.

Take care of waste for recovery back to retail.

Sample control, camera control.

No water by cleaning.

Do it Diesel Care way.

All sizes, to depot tank.

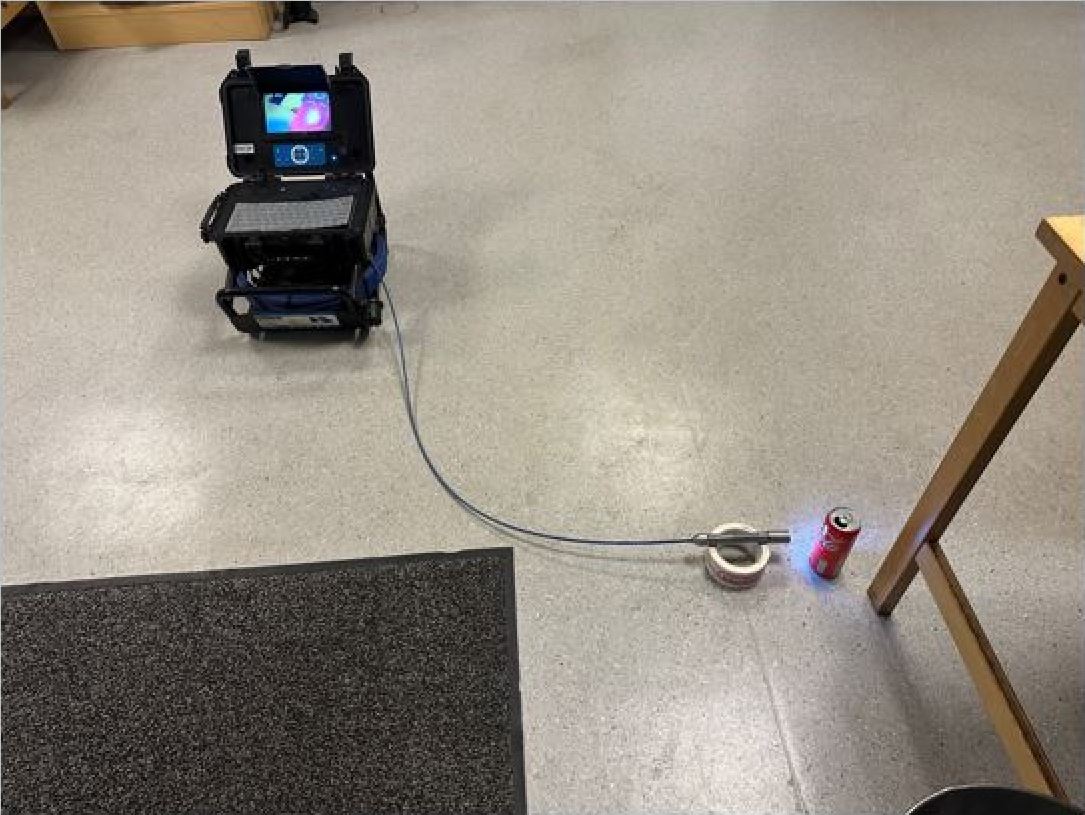

Flexible Diesel fuel sampler

Make your samples from different heights in your tank, to find your solution.

Sample tank 0-3-7-10-50-100 cm from bottom, gives you best result.

Sample tank 0-3-7-10-50-100 cm from bottom, gives you best result.

Contact

- Kongevegen 14, Kongsvinger, Norge

- Mon-Fri - 08:00-16:00